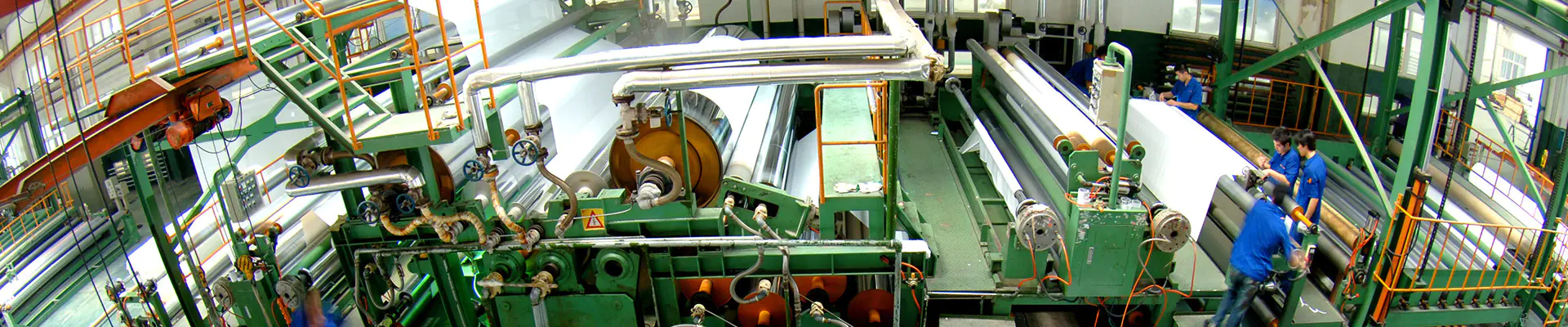

Welcome to professional plastics manufacturer

PVC welder protection curtains are specialized barriers designed to safeguard workers and workspaces from welding hazards. Here are their key applications and advantages:

✅ Arc Flash Protection

✅ Sparks & Spatter Containment

✅ Work Zone Partitioning

✅ Multi-Station Screening

🏭 Metal Fabrication Shops

🔧 Automotive & Aerospace

⚡ Shipbuilding & Heavy Machinery

🏗️ Construction Sites

✔ Material

✔ Safety Enhancements

✔ Customization

| Feature | PVC Curtains | Metal Screens | Fabric Blankets |

|---|---|---|---|

| Visibility | ✔ Transparent options | ✖ Opaque | ✖ Opaque |

| Mobility | ✔ Easy to reposition | ✖ Fixed | ✔ But flammable |

| Durability | ✔ 2-5 year lifespan | ✔ Long | ✖ Short |

| Cost | $$ Medium | $$$ High | $ Low |

Need a welding curtain solution? We offer:

Contact us for flame test reports and installation guidance!

Clear Low Temperature PVC Sheets

Clear Low Temperature PVC Sheets

Clear Standard PVC Strip Rolls

Clear Standard PVC Strip Rolls

Standard Economy PVC Strip Rolls

Standard Economy PVC Strip Rolls

Low Temperature Economy PVC Strip Rolls

Low Temperature Economy PVC Strip Rolls