In today’s industrial and commercial environments, maintaining optimal working conditions is crucial for productivity and operational efficiency. PVC strip curtains have emerged as a practical solution for addressing two critical challenges: noise pollution and climate control. These flexible barriers, made from durable polyvinyl chloride, offer an economical yet highly effective way to enhance workplace environments across various sectors.

At Cosyst Devices, with our extensive 25-year experience in providing industrial solutions, we’ve witnessed how these unassuming installations can transform workspaces. This article examines the dual functionality of PVC strip curtains in sound attenuation and thermal management, along with their diverse applications in different settings.

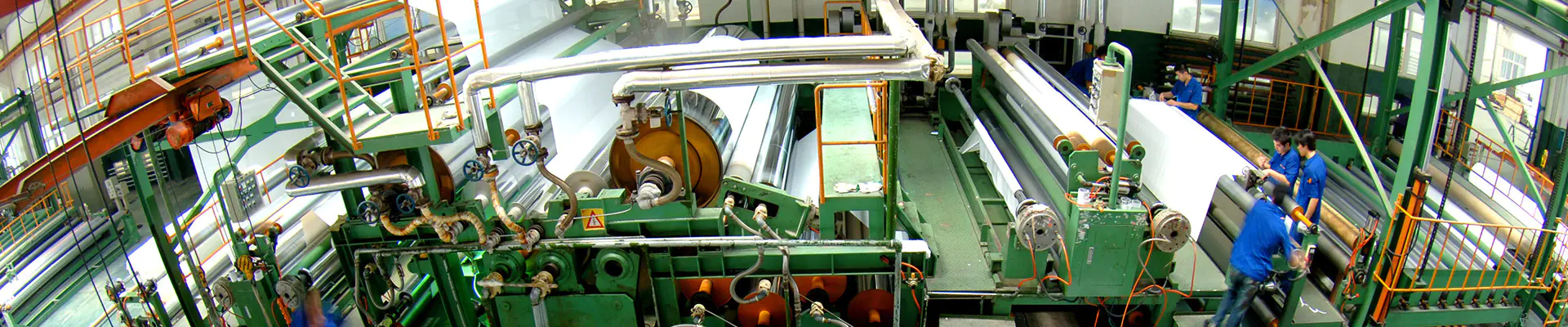

Constructed from resilient PVC material, these curtains consist of overlapping translucent strips that form a permeable barrier. They allow uninterrupted movement of personnel and equipment while effectively segregating spaces. Their transparent design ensures natural light penetration and maintains visual connectivity, making them particularly valuable in areas requiring both separation and visibility.

Our product range at Cosyst Devices encompasses various configurations, from lightweight residential plastic door screens to heavy-duty industrial-grade thermal curtains. These solutions help organizations optimize their operational environments while reducing energy expenditures associated with climate control systems.

Industrial facilities often grapple with excessive noise from machinery and equipment, which can adversely affect worker concentration and well-being. PVC strip curtains serve as an efficient sound dampening solution without the need for structural modifications.

The overlapping PVC strips create an acoustic barrier that absorbs and deflects sound waves. Unlike solid partitions, these flexible curtains effectively reduce noise transmission between areas while maintaining accessibility. The material’s density plays a crucial role in sound attenuation, with thicker variants offering superior noise reduction capabilities.

This vibration-dampening property makes them particularly effective in environments with heavy machinery, where they can significantly lower ambient noise levels.

By implementing these curtains, businesses can achieve compliance with noise regulations while improving workplace comfort.

Beyond acoustic benefits, PVC strip curtains excel in maintaining stable thermal environments. They form an effective seal against air transfer, making them invaluable for climate-controlled spaces.

The overlapping strips create an insulating air pocket that minimizes heat exchange between adjacent areas. In refrigerated spaces, they prevent cold air loss while blocking warm air infiltration, reducing refrigeration system workload. For air-conditioned environments, they maintain cool temperatures by limiting warm air ingress during frequent door openings.

These applications demonstrate how PVC curtains contribute to significant energy savings and operational efficiency.

The benefits of PVC strip curtains extend beyond their primary functions:

When sourcing PVC strip curtains, consider these factors:

Cosyst Devices offers tailored solutions to meet these diverse requirements, from standard plastic curtain rolls to specialized industrial-grade installations.

Clear Low Temperature PVC Sheets

Clear Low Temperature PVC Sheets

Clear Standard PVC Strip Rolls

Clear Standard PVC Strip Rolls

Standard Economy PVC Strip Rolls

Standard Economy PVC Strip Rolls

Low Temperature Economy PVC Strip Rolls

Low Temperature Economy PVC Strip Rolls